Special Mention

2008 Skyscraper Competition

Paul Burgstaller, Ursula Faix, Michael Kritzinger

Switzerland

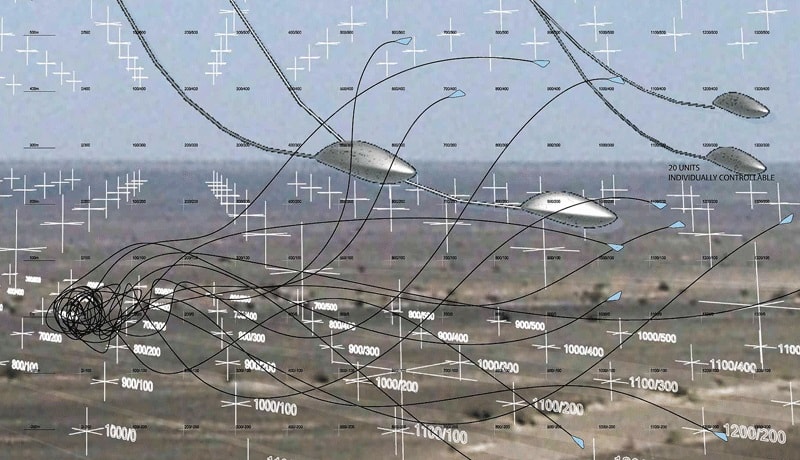

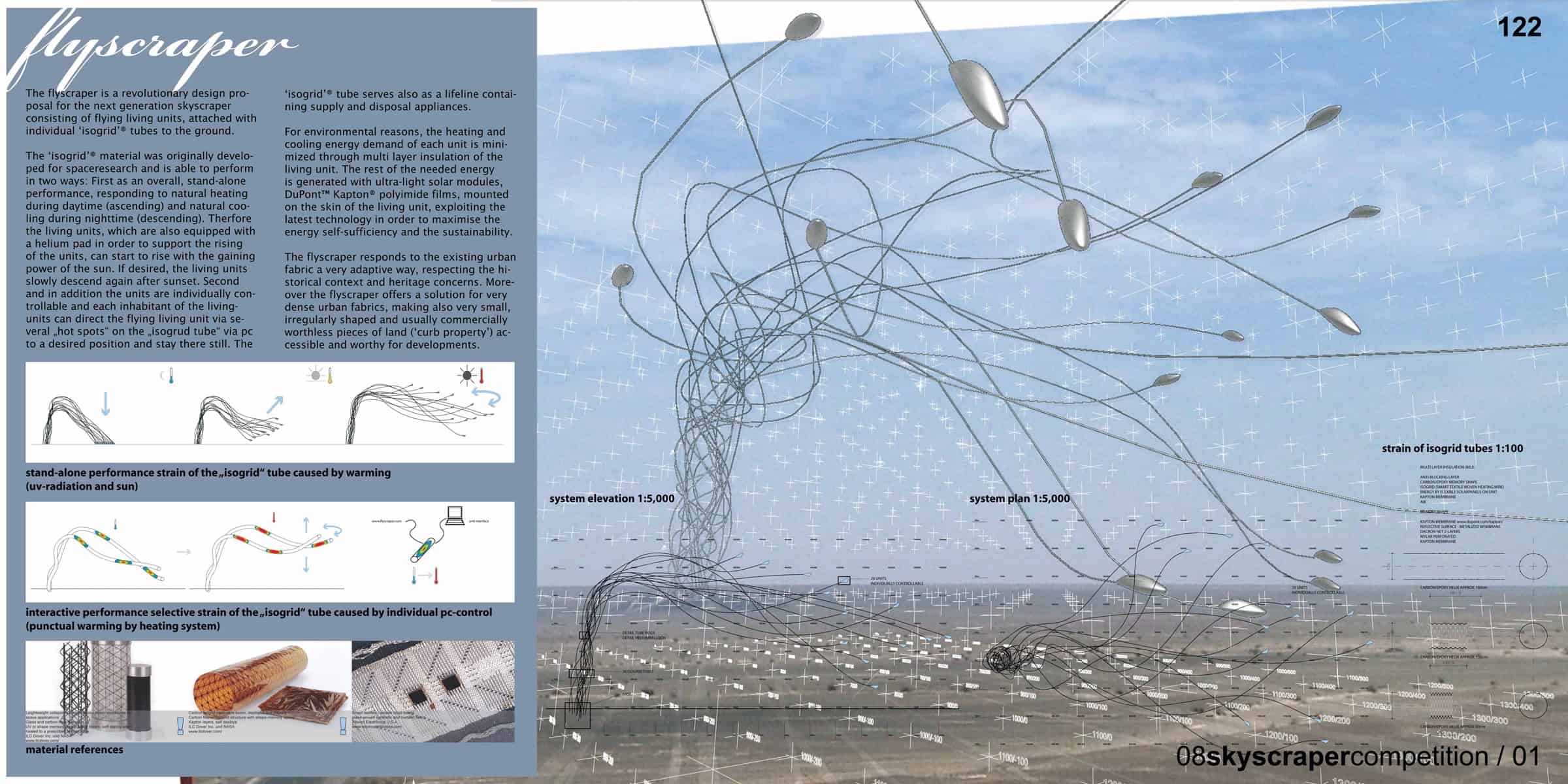

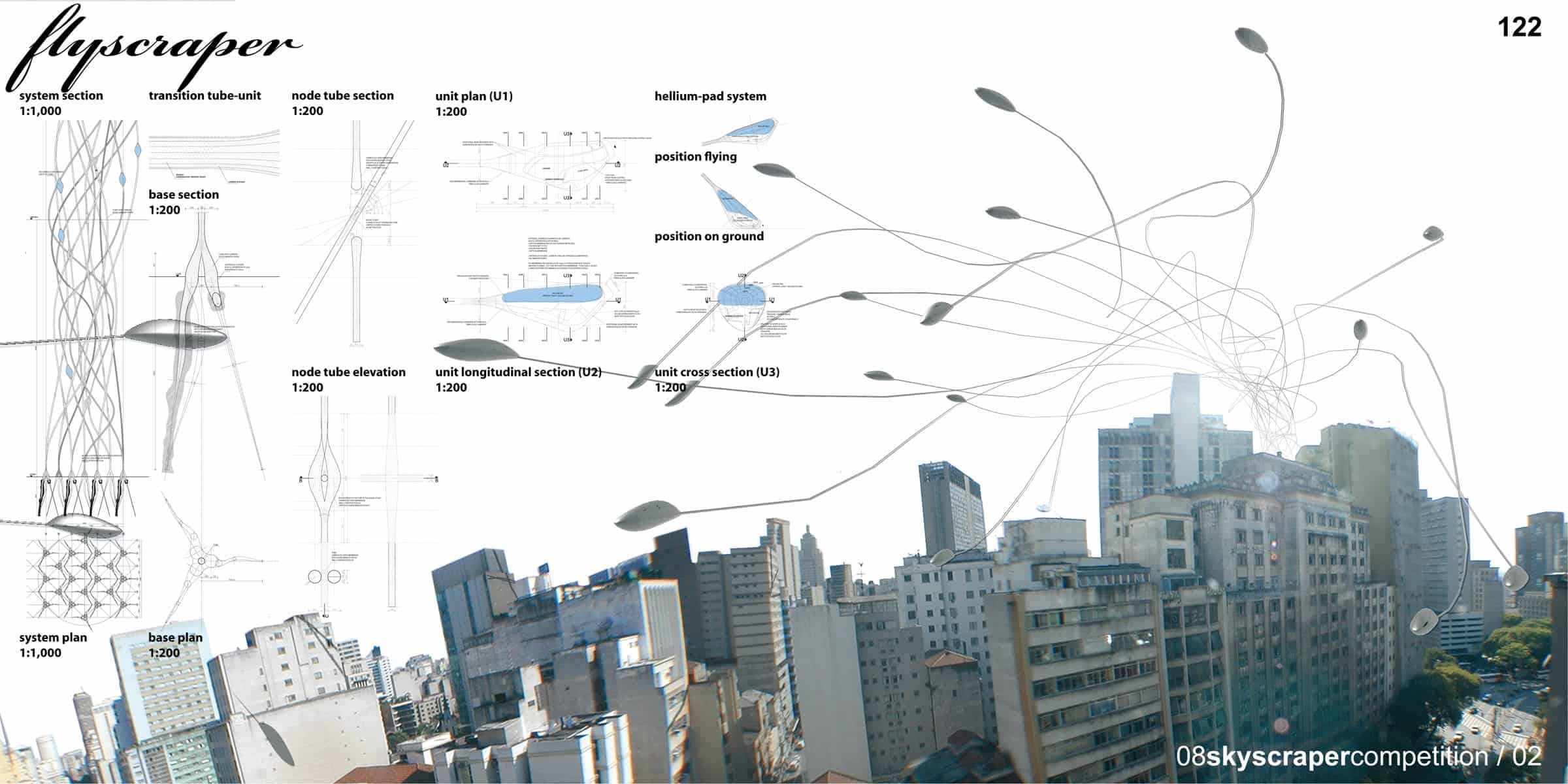

The ‘flyscraper’ is a revolutionary and visionary design proposal for the next generation skyscraper, consisting of flying living units, attached with individual ‘carbon isogrid’ tubes to the ground. In urban areas across the world we see two phenomena: fast growing metropolitan areas, as well as shrinking cities. The ‘flyscraper’ is designed for both: deserted as well as congested urban areas. Moreover the ‘flyscraper’ responds to the existing urban fabric in a very adaptive way, respecting the historical context and heritage landmarks. In addition, the ‘flyscraper’ offers a solution for very dense urban fabrics, making small, irregularly shaped, and usually commercially worthless pieces of land (‘curb property’) accessible and worthy for developments; since only ground for the foundation of the ‘carbon isogrid’ tubes is needed.

The ‘carbon isogrid’ material was originally developed for space research. It is a carbon filament wound structure with shape-memory epoxy which is able to deploy or fold when heated to a prescribed temperature. This allows performing in two ways: first as an overall, stand-alone element, responding to natural heating during daytime (ascending) and natural cooling during night time (descending). The living units, which are also equipped with a helium pad, in order to support the rising of the units, can start to rise with the gaining power of the sun, then slowly descend again after sunset. Secondly, the units are individually controlled by each inhabitant, who can direct them via several shape-memory epoxy “hot spots“ on the ‘carbon isogrid’ tube from a PC to any desired position.

The ‘isogrid’ tubes are anchored with thee root-like pile-foundations to the ground. In the lower part of the ‘flyscraper’, special nodes, a widening of a tube, are intentionally interwoven with the ‘carbon isogrid’ tubes, so the floating tubes can move elastically and won’t mingle accidentally. Therefore, the lower part of the structure forms a very coarsely meshed tissue, which is still navigable. Small helium pads, incorporated to the ‘carbon isogrid’ tubes, support the rising of the structure. Past the interwoven part of the structure, the tubes can move individually; crashes are avoided by a security system that keeps units at a certain distance from each other.

The frame of the living unit is made of lightweight fiberglass laminate, reinforced with additional carbon Kevlar delta stringers. The topcoat is made of sand blasted epoxy resin. Each living unit is equipped with a large living area, which is designed in a boomerang shape so living would work for both positions: the flying position and the static position on the ground. Moreover, a kitchen, bathroom, bedroom and the PC control-station are an integral part of the living unit. For environmental reasons, the heating and cooling energy demand of each unit is minimized through multi layer insulation of the living unit’s outer skin. The rest of the required energy is generated by ultra-light solar modules, DuPont Kapton polyimide films. Those high-tech solar modules are mounted on the skin of the living unit, exploiting the latest technology in order to maximize their self-sufficiency and sustainability.

This work is licensed under a Creative Commons License permitting non-commercial sharing with attribution. https://creativecommons.org/licenses/by-nc-nd/4.0/