Special Mention

2009 Skyscraper Competition

Stefan Shaw, John Dent

United Kingdom

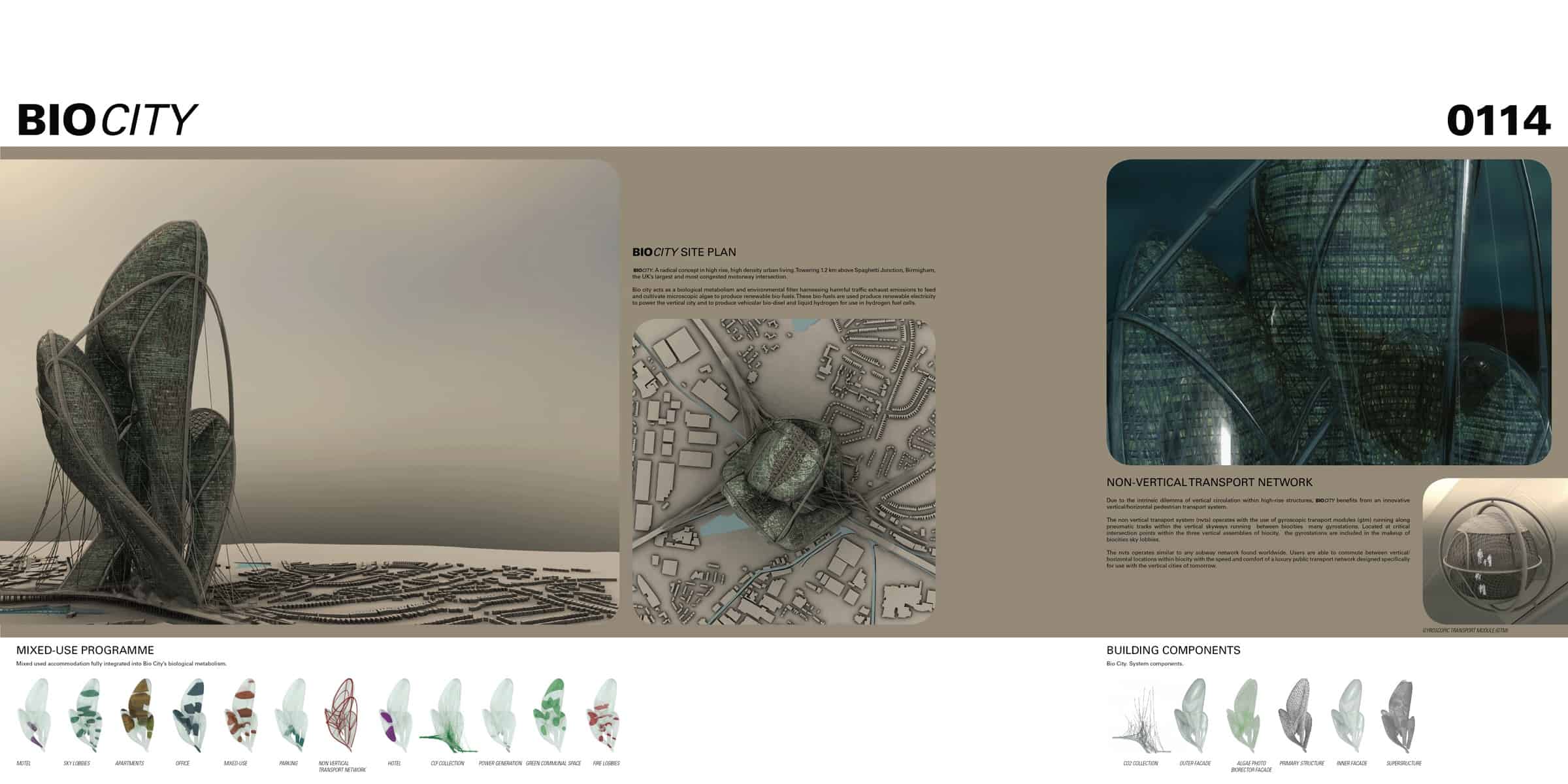

A closed loop metabolic system

A completely closed metabolic cycle in which traffic exhaust emissions are harnessed via CO2 collectors in order to feed algae grown in photo bio-reactors within the building’s facade. Algae and natural by-products produced during algae cultivation are then refined to produce renewable energy sources.

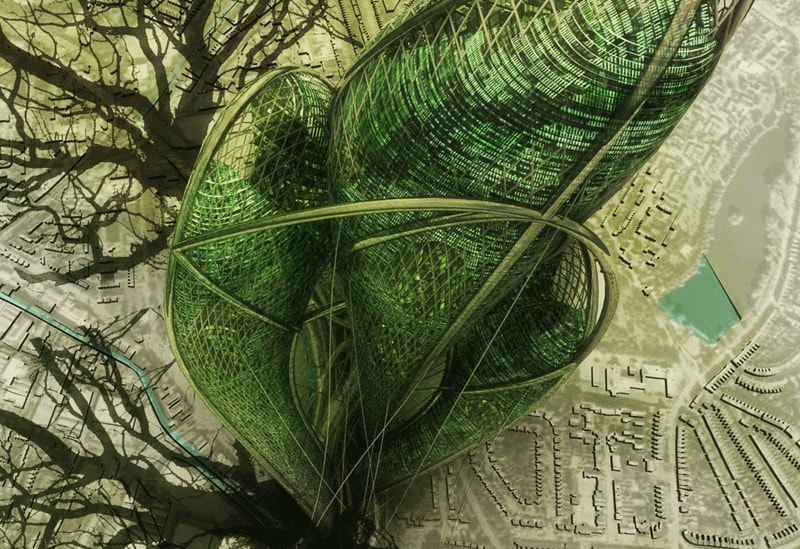

Towering 1.2 km above Spaghetti Junction, Birmingham, the UK’s largest and most congested motorway intersection, the scheme portrays a radical concept in high rise, high density urban living. Benefitting from positive solar orientation, in order to maximize solar acceptance toward the dynamic photo bioreactors which are built into the facade, BIOCITY acts as a an environmental filter, harnessing harmful traffic exhaust emissions in order to feed and cultivate microscopic algae to produce renewable bio-fuels. These bio-fuels are used to produce renewable electricity to power the vertical city and to cultivate vehicular bio-diesel and liquid hydrogen for use in hydrogen fuel cells.

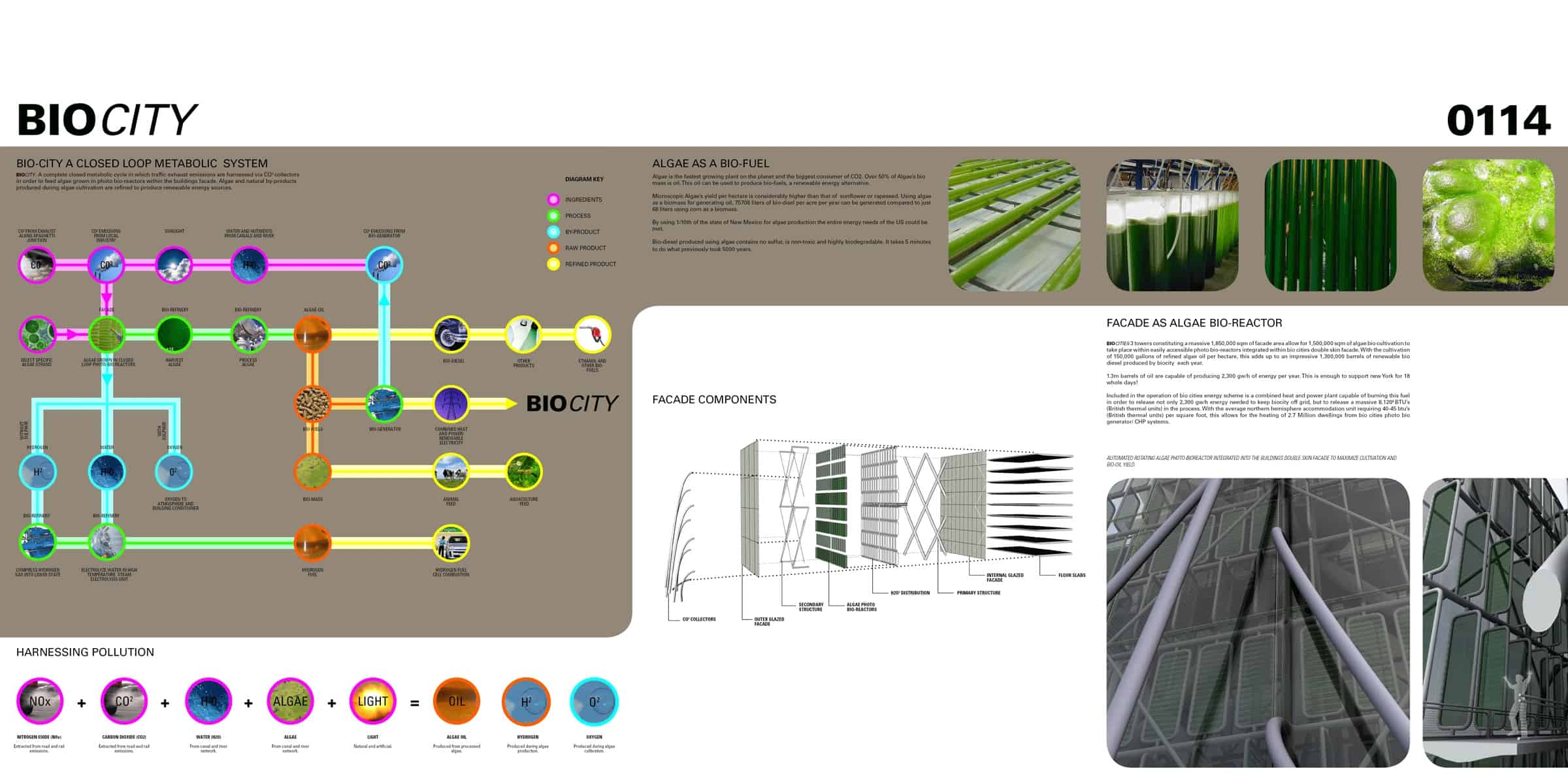

Algae as bio-fuel

Over 50 percent of Algae’s bio mass is oil. This oil can in turn be refined in order to produce renewable and thus sustainable bio-fuels. Left wild, algae can cause massive destruction to aqua based eco systems by starving the water of natural light; however, by harnessing the raw potential of this amazing plant, energy concerns around the globe could easily be neutralized with the use of innovative photo-bioreactor technologies.

Algae are the fastest growing organic material on the planet – ten times faster than trees – with the more efficient species doubling their volume every 6 hours. Microscopic Algae’s yield per hectare is considerably higher than that of sunflower or rapeseed. Using algae as a biomass for generating oil, 75000 liters of bio-diesel per acre per year can be generated, compared to just 68 liters using corn as a biomass. Microscopic microalgae are typically free floating in the water and encompass several groups of relatively simple organisms that capture light energy through photosynthesis, using it to convert inorganic substances into organic matter. Bio-diesel produced using algae contains no sulfur, is non-toxic and highly biodegradable.

Façade as algae bio-reactor

Since algae need sunlight, carbon-dioxide and water for their growth, they can be cultivated in open ponds. However, the unassisted growth in open ponds is slow, alternatively, for use in the vertical city, algae is grown in closed photo-bioreactors, where the environment is better controlled.

Bio-cities

Three towers constituting a massive 1,850,000 square meters of facade area, allow for algae bio-cultivation to take place within plastic tube photo bio-reactors integrated within the double skin facade. With the cultivation of 150,000 gallons of refined algae oil per hectare, this adds up to an impressive 1,300,000 barrels of renewable bio diesel produced by Bio-City each year.

Non-vertical transport system

Due to the intrinsic dilemma of vertical circulation within high-rise structures, Bio-City benefits from an innovative vertical-horizontal pedestrian transport system.

The non vertical transport system operates with the use of gyroscopic transport modules running along pneumatic tracks within the vertical skyways running between bio-cities. The Non-vertical transport system operates as any subway network found worldwide. Users are able to commute between vertical-horizontal locations within Bio-City with the speed and comfort of a luxury public transport network designed specifically for use with the vertical cities of tomorrow.

This work is licensed under a Creative Commons License permitting non-commercial sharing with attribution. https://creativecommons.org/licenses/by-nc-nd/4.0/